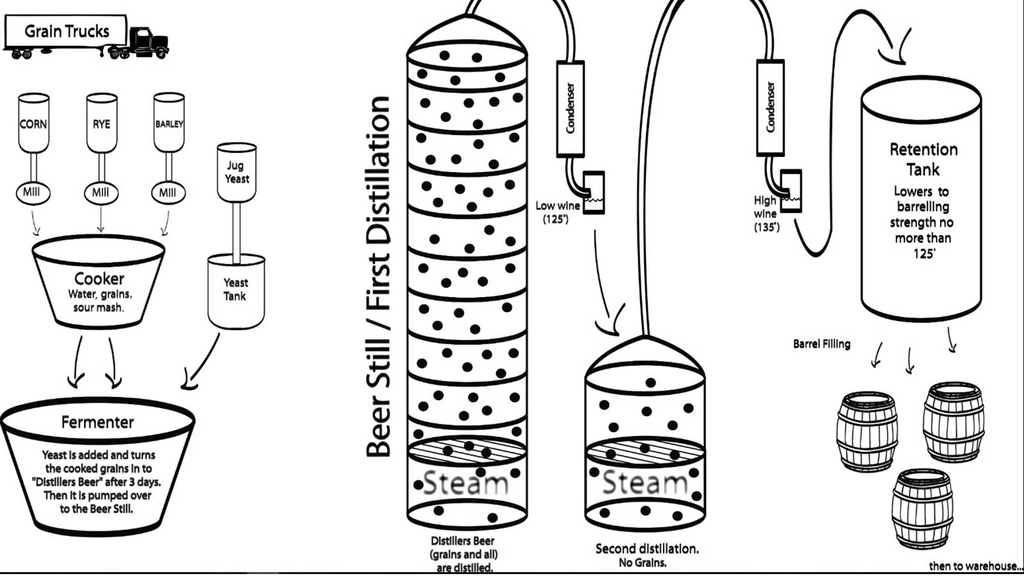

Sour Mash Process

Sour mash is used in the distilling industry and is a process that uses leftover material from an older batch to start the fermentation process of the next. You will often see American style Whiskey’s described as a “ Sour Mash” - the reality is almost all Bourbon’s on the market today use this process to add consistency to their product and to kick start the fermentation process. Yeast needs the perfect pH environment to work efficiently and to control the flavour of the bourbon being created. Leftover yeast is an excellent source of food for live yeast, and similar to the development of Kombucha and live ferments, we can use old yeasts to help control the environment of yeast and bacteria.

After the addition of neutral water to a mash, the mash has a pH of approximately 7 (neutral) in which the yeasts can't work properly. The addition of a part of the very sour stillage (pH 5.0 - 5.4) leads to an acidification of the entire mash. After the stillage has been added, the mash has a pH of about 5.4 to 5.8, which is ideally acidic for the yeasts to work properly and get that next fermentation started! The more efficient a distillery can become in this process the faster they can get their bourbon into the hands of its passionate drinkers.

These days almost all bourbon whiskey’s go through the sour mash process.

A similar leftover yeast production, referred to as Dundar, is often used in Jamaican rum production.